English

English Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Yadda ake yin tsarin sarrafa madaidaicin injin

2021/07/06

Yadda ake yin tsarin sarrafa madaidaicin injin

☞ Za mu rarrabe tare da rarrabasu mafita ga matsalar rashin jituwa da girman geometrical a cikikerawa a fannoni huɗu: kayan aiki, kayan aiki, kayan aiki, da kayan aikin injin, da gabatar da wasu shawarwari.

A cikinsarrafa inji, haɗin kai da aka haɗa da kayan aikin injin, kayan aiki, kayan aiki da kayan aikin aiki ana kiranta tsarin aiwatarwa. A yayin aiwatarwa, saboda kasancewar kurakurai iri -iri na farko a cikin tsarin aiwatarwa, an lalata madaidaicin alaƙar geometric tsakanin kayan aikin da kayan aiki, kuma girman geometric ya fita daga haƙuri. Gabaɗaya, kurakurai na asali waɗanda za su iya faruwa yayin aiki sun kasu kashi biyu, wato, “a tsaye” kurakurai na asali da suka danganci yanayin farkon tsarin aiwatarwa da kuma “tsauri” kurakurai na asali da suka shafi tsarin sarrafawa. Abubuwan da ke biyowa suna ba da mafita ga matsalar ƙirar ƙirar geometric mara haƙuri machining sassadaga fannoni huɗu: kayan aiki, kayan aiki, kayan aiki, da kayan aikin injin.

Kayan aiki

1) Yakamata a bi ƙa'idar gabaɗaya, wato, ma'aunin farko, sannan wasu, fuska ta farko, rami na farko, maigida sannan na biyu, m da farko sannan lafiya, m da rabuwa mai kyau.

2) Kafin matakin ƙarshe na aiwatarwa, sassauta farantin matsin lamba, sakin walƙiya da kyau, da kuma damfara kayan aikin bayan sake daidaita shi. Domin tabbatar da amincin aiki da ingancin sarrafawa, ana ba da shawarar samun mafi girman ƙimar juzu'i don haɗa haske ta hanyar tabbatar da gwaji da yin madaidaicin ƙarfin wutar lantarki.

3) Matsayin aiki na mai matsawa yakamata ya zama mai ƙarfi, kuma maƙasudin aikin ya lalace saboda ba ainihin ma'ana bane. Akwai mafita 3:

com 'Rarraba ainihin wanda ke matsawa zuwa dunƙule mai ƙarfi biyu, amma ku kula da sauyawa Tsarin ƙulli, idan ya cancanta, ana buƙatar sake haɗa kayan aikin.

etKa saita maƙallan ƙulli don kayan aikin, kuma bayan an kammala dukkan hanyoyin, yanke shawara ko cire shugaban aikin gwargwadon ko ya shafi taron yanki.

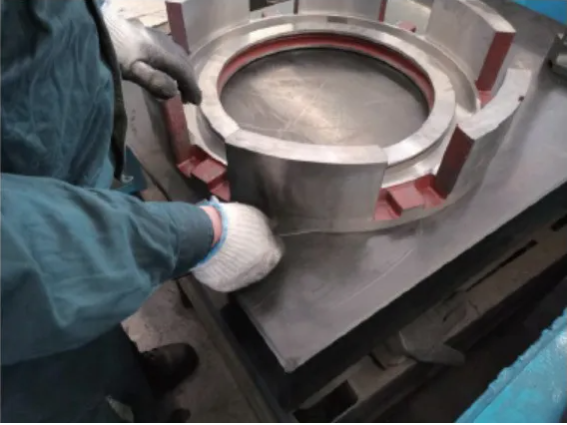

â ‘¢ Ana ba da tallafi na mataimaka a wuraren raunin tsarin ƙulle (duba hoto 1). Wasu tallafi na taimako na hydraulic akan kasuwa na yanzu na iya samun tallafin "sifilin sifili". Zuwa

Taimakon taimako1

4) Tabbatar cewa shimfidar wurare na kayan aikin da kayan aikin suna da madaidaicin madaidaiciya. Ana nuna rajistar kai-tsaye a cikin Hoto 2.

Idan jirgin saman yana da girma, za a iya maye gurbin shimfidar shimfidar wuri tare da nau'in toshe don guje wa gurɓataccen gurɓataccen gurɓataccen abu wanda ke haifar da kayan aiki da babban jirgin da ya dace;

idan ba za a iya tabbatar da lalatattun kayan aikin ba, fatar jan ƙarfe, goge takarda da firam ɗin Warp, da dai sauransu, daidaita shimfidar wuri sannan a matse shi don sarrafawa.

Flatness kai duba

5) A yayin aiwatar da injin, ana amfani da yankan ruwa don watsa zafi a cikin lokaci don rage lalacewar yanayin aikin.

6) An shirya maganin tsufa kafin a gama ƙera injin don gama sakin damuwar cikin aikin.

7) Lokacin juyawa, don ɓangarori masu katanga, yi amfani da jaws masu taushi ko tsagagen abin wuya don ƙullewa, ko amfani da matsewar fuska ta ƙarshe maimakon matsawar da'irar.

8) Lokacin juyawa, ana aiwatar da juyi na juyawa gwargwadon naƙasasshe, wato, adadin naƙasasshen daidai an riga an sarrafa shi a akasin shugabanci,

da adadin naƙasasshen juyi da adadin naƙasasshe sun soke juna bayan an kammala aikin.

9) Lokacin jujjuya manyan kayan aikin da ba daidai ba, yakamata a aiwatar da ma'aunin nauyi gwargwadon matsayin tsakiyar taro na kayan aikin don rage ƙarfin centrifugal.

Bangaren kayan aiki

1) Kafin hakowa, gajiya da reaming, idan akwai tsarin rabin bango a ɓangaren injin, dole ne a fara cire rabin rabin bangon;

idan sashin kayan aikin shine farfajiya mara fa'ida, dole ne a fara fuskantar farfajiya ta farko don tabbatar da ƙarfi iri yayin yanke.

2) Kafin injin, bincika radial da runial na kayan aiki daidai da ƙa'idodi masu dacewa.

3) An hana masu riƙe kayan aiki daga buguwa da karcewa, kuma ana amfani da kayan aiki na musamman don tsaftace ramukan taper na injin injin a kai a kai.

4) Sarrafa tsawon kayan aikin, gwargwadon iko don tabbatar da cewa kayan aikin yana da isasshen diamita, don tabbatar da cewa kayan aikin suna da ƙarfi.

5) Don kayan aiki tare da buƙatun daidaitattun ƙima, dole ne a daidaita kayan aiki da ƙarfi kafin sarrafawa.

6) Daidaita sigogi na yankan da kusurwar kayan aiki, da sauransu, don sarrafa ƙarfi, zafi da sa kayan aiki yayin aiki.

7) Yi amfani da kayan aiki na musamman na anti-vibration da anti-vibration.

Siffar gyara

1) Inganta hanyar ƙulli don hana maɓallin shigarwa na dunƙule matsawa da maƙasudin goyan baya na farantin matsin lamba daga kasancewa ɗaya akan kayan aiki ɗaya kuma ɗayan akan kayan aikin injin don hana tsayayyen abin daga matsi na matsawa da haifar da nakasawa sosai.

2) Kayan aikin dole ne ya sami isasshen rigidity.

3) Lokacin da kayan aikin ya karɓi mandrel don sakawa, kuma an ba da mandrel tare da zaren matsawa, dole ne zaren ya zama ƙasa don tabbatar da madaidaicin zaren da ƙarshen ƙarshen matsayi na mandrel.

4) Yi tabbataccen daidaitaccen daidaitaccen daidaituwa akan madaidaicin juyawa don sarrafa jujjuyawar centrifugal na tsayayyen lokacin da yake juyawa.

Kayan aikin injin yana dubawa kuma yana tabbatar da kayan aikin injin daidai da yarda da kayan aikin injindaidaitattun ma'auni, kamar bincika tsayuwar madaidaiciyar mashin ɗin injin da teburin aiki, da motsi na dunƙule.

Kammala jawabin

1) Lokacin da kayan aikin, musamman sabon samfurin, ya kasance ba shi da haƙuri a cikin ma'aunin geometric, da farko za a tantance wane irin nakasa ke haifar da shi, sannan a nemi mafita mai dacewa gwargwadon maganin nakasa.

2) Binciko amfani da fasahar bincike na iyakance na komfuta don yin bincike game da ɓarna na tsarin aiwatarwa a gaba, wanda ya dace da ci gaba da inganta tsarin aiwatarwa.

3) A cikin aikin yau da kullun, dole ne mu kasance masu kyau a taƙaice hanyoyin magancewa da zana rabe -rabe daga juna, don haɓaka ƙimar samfur gaba ɗaya.